stencil technology

HIGH-PRECISION PRODUCTION

OF SMT STENCILS

Smart stencils

THE QUALITY BEHIND

BEST PRINTING RESULTS

There are good reasons to rely on our high-precision SMT stencils for solder paste printing.

The quality of SMT stencils is crucial in order to obtain a successful printing result. Our laser-cut stencils are all submitted to a guaranteed safety check.

With additional surface finishing by nano-cutting or electropolishing, you get the optimum result for solder paste printing and circuit board assembly.

QUALITY FACTORS

To optimize your solder paste printing, we use the following systems for production of SMT stencils of the highest precision:

LPKF-TURBOCUT-SYSTEM

special lens rotation mechanism in the laser cutting head to optimize the contours of circular openings to almost 100% (especially for BGAs)

LOEWER DISCMASTER 4TD-100

After-treatment by our FSL precision brushing equipment BM2/6 takes care of thorough, extra-fine polishing of all the laser stencils we supply.

THE LATEST LASER-CUTTING TECHNOLOGY

with quick check system (CCD camera-based measuring system to monitor pad location and size)

MOTORIZED BEAM EXPANDER

software-controlled adjustment of the laser focus position for every desired thickness of material. The resulting precise focus setting ensures an optimally conical shape and low-residue laser-cut edges.

QUALITY MANAGEMENT

100% SECURITY CHECK

We test the quality of SMT stencils with LPKF StencilCheck. The software creates a scanned image of the stencil and compares it to the production data. Discrepancies are displayed graphically on the screen. All test results can be summarized in a report and traced back. This is our guarantee of complete quality management.

QUALITY MANAGEMENT

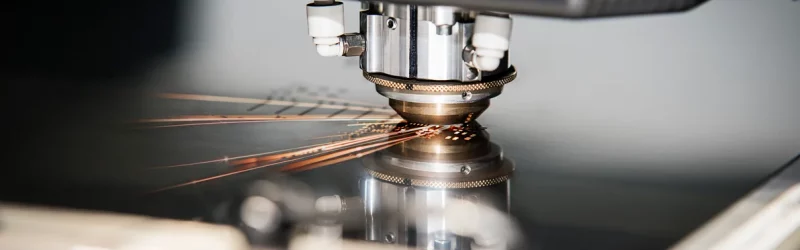

LASER CUTTING

Extremely high energy density and focus make the laser an optimal tool for making precision cuts, and thus for the manufacture of high-precision SMT stencils.

The laser source we use generates a highly focused laser beam with a wavelength of 1064 nm (infrared). At its focal point, the energy density is so high that it can cut stainless steel sheets of 500 μ thickness. The accuracy of the laser systems is ± 2 µm. The thermal stress on the material along the cut is extremely small.

Surface finishing

NON-REFINED SMT STENCILS

The process of nano-finishing offers additional protection and increases the durability of printing stencils.

Surface finishing

ELECTROPOLISHED SMT STENCILS

Electropolishing improves a number of properties of metallic surfaces in one operation.