Electropolishing

SURFACE FINISHING

FOR

SMT STENCILS

ELECTROPOLISHED PRINTING STENCILS

FOR THE OPTIMUM

PRINTING RESULT

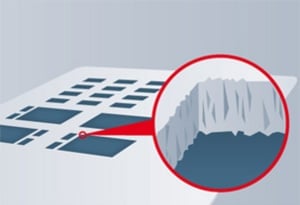

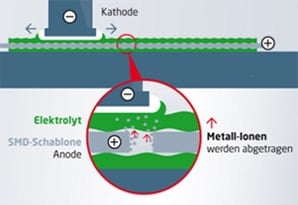

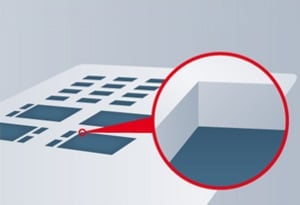

The laser cutting of SMT stencils produces melt residue on the inner walls of the openings, which can affect the quality of the printing result.

Electrochemical polishing and deburring (electro-polishing) improves a number of metallic surface properties in one operation. The micro-roughness of the template surface is significantly reduced. The opening walls are smoothed and the finest ridges removed.

For particularly delicate applications, standard surface treatment (double-sided brushing) is not sufficient. In this case, a surface treatment by electro-polishing and/or nano-coating is recommended.

eigens für Photocad entwickelte Elektopoliturmaschine der Firma Poligrat

Automatischer Poliervorgang in geschlossener Kammer

Electropolishing

SPECIALLY DEVELOPED

SURFACE FINISHING

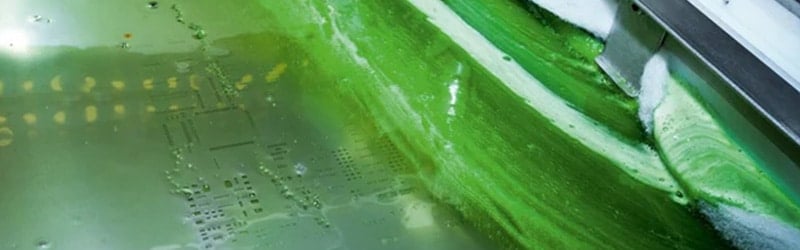

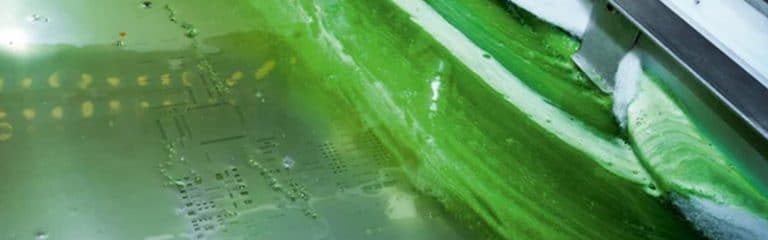

Photocad is the only manufacturer in Germany to use the Poligrat EP110, L250-25 automatic electro-polishing system for the electro-chemical surface treatment of SMT stencils.

The system specially developed by Poligrat for Photocad ensures that the polishing process takes place in a closed chamber, controlled by a Siemens CNC control system. Work safety is significantly improved compared with conventional electro-polishing by hand. In addition, the automation guarantees consistently high quality.

In addition to electropolishing, Photocad offers surface nano-coating. For an ideal solder paste printing result with high requirement specifications, we recommend combining both surface finishing processes – electropolishing and nano-finishing.

SURFACE POLISH

the

PROCESS

Phase 1

Phase 2

Result

ADVANTAGES OF ELECTROPOLISHING:

- Using electropolishing elicits a significant improvement in printing, particularly for very small pad apertures, as solder paste is distributed better thanks to the smoothed walls

- Electropolishing only works on a microscopic scale, and does not change the shape or macrostructure of the component. The component, in this case the SMT stencil, is not subjected to any mechanical or thermal stress

- The stencil is easier to clean

- The results can be reproduced with a higher level of accuracy

FAQ

This type of surface requirement is particularly suitable for delicate application and the smallest components. Therefore, we offer SMD stencil electro-polishing in the ADVANCED and PERFORMANCE product lines.

For simple applications, standard surface treatment (double-sided brushing) is sufficient. The process of electro-polishing is used in delicate structures. The most exacting requirements additionally require nano-refinement. To overview